The fuel used in model rockets is a key ingredient that drives these miniature marvels to astonishing heights. Understanding the composition of this fuel and how it functions within the rocket’s engine is crucial for achieving successful launches. Stay tuned to unravel the mystery behind the fuel that powers these aerial wonders and learn how it plays a vital role in the thrilling world of model rocketry.

Ingredients and Safety Measures

When creating fuel for model rockets, it is crucial to carefully measure and mix specific ingredients while adhering to strict safety precautions. The fuel composition consists of 58 grams (2.0 oz) of potassium nitrate, 29 grams (1.0 oz) of granulated white sugar, 13 milliliters (0.055 c) of Karo syrup, and 30 milliliters (0.13 c) of distilled water. Safety equipment such as gloves and protective eyewear must be worn throughout the process. Clear goggles providing full coverage and elbow-length laboratory gloves are recommended. When mixing the ingredients, vigorously shake the potassium nitrate and sugar in a disposable container. After mixing, store the rocket fuel in a dry, cool place following launch safety guidelines. It is vital to understand the fuel composition, use appropriate safety equipment, employ correct mixing techniques, explore suitable storage solutions, and prioritize launch safety to ensure a successful model rocket launch.

Mixing and Molding Procedures

To properly execute the mixing and molding procedures for model rocket fuel, ensure precise measurement and controlled heating of the ingredients in a suitable container. When shaping the rocket fuel, consider the following:

- Fuel Composition: Mix potassium nitrate and sugar thoroughly before heating.

- Shaping Techniques: Mold the cooled mixture to the desired shape using appropriate molds.

- Temperature Control: Heat the ingredients on an electric cooktop, avoiding gas or open flames.

- Safety Guidelines: Wear protective gear, work in a well-ventilated area, and store the rocket fuel in a dry, cool place.

Following these steps meticulously ensures the creation of consistent and reliable rocket fuel for your model rockets. Remember to adhere to safety precautions at all times, experiment with different fuel compositions to optimize performance, and store the molded fuel in airtight containers away from air and moisture to maintain its potency.

Launching Protocol and Testing

For optimal model rocket performance, adhere to established launching protocols and conduct thorough testing to ensure safe and efficient operation. When launching your model rocket, follow a strict launching protocol to guarantee safety and success. Before the launch, conduct comprehensive safety testing to assess the functionality and reliability of the rocket fuel. During testing, ensure proper ventilation, maintain safety distances, and record performance data for analysis. Altitude recording is crucial for evaluating the rocket’s flight capabilities accurately. Analyze the performance data to identify any areas for improvement. If necessary, make fuel composition adjustments based on the performance analysis to optimize the rocket’s efficiency and altitude reach. Remember that launching protocols, safety testing, performance analysis, altitude recording, and fuel composition adjustments are all integral parts of ensuring a successful and safe model rocket launch.

Community Insights and Precautions

Considering the insights and precautions shared by the community, it is essential to adhere to the recommended safety measures and legal guidelines when engaging in the creation and storage of model rocket fuel.

Community Insights and Precautions:

- Safety Guidelines

- Follow safety precautions shared by the community.

- Wear appropriate protective gear like gloves and goggles.

- Ensure proper ventilation during fuel testing.

- Adhere to recommended safety distances and precautions.

- Community Engagement

- Engage with the community for tips and advice on fuel composition.

- Share your experiences and learn from others in the rocketry community.

- Collaborate on safety measures and best practices.

- Stay informed about any updates or changes in safety protocols.

- Fuel Composition

- Understand the composition of the rocket fuel you are using.

- Experiment with different fuel compositions for optimal performance.

- Analyze the performance data to refine the fuel mixture.

- Adjust the fuel composition based on performance analysis for desired results.

- Legal Implications

- Be aware of any legal restrictions regarding the creation and storage of rocket fuel.

- Understand the laws governing homemade rocket fuel in your location.

- Ensure compliance with legal guidelines to avoid any legal implications.

- Seek legal advice if unsure about the legality of your rocket fuel activities.

Molding Techniques and Storage Tips

Utilize appropriate molding techniques and storage methods to ensure the integrity and longevity of your model rocket fuel. When shaping the fuel, use suitable molds to create consistent shapes like balls, cakes, or snakes. Ensure to handle the warm fuel with gloved hands to prevent crumbling and press it firmly into the desired shape for storage. Store the molded rocket fuel in an airtight plastic container away from air and moisture to maintain its potency. Additionally, choose a container with a secure locking lid or a large plastic zipper bag if needed. Label containers stored in the refrigerator for easy identification. Avoid reheating the rocket fuel once it has been shaped and cooled. Remember to keep a fire extinguisher nearby for emergencies and follow all safety precautions while handling and shaping the fuel to prevent accidents. Proper molding methods and storage solutions are crucial for effective fuel preservation and maintaining the performance of your model rocket.

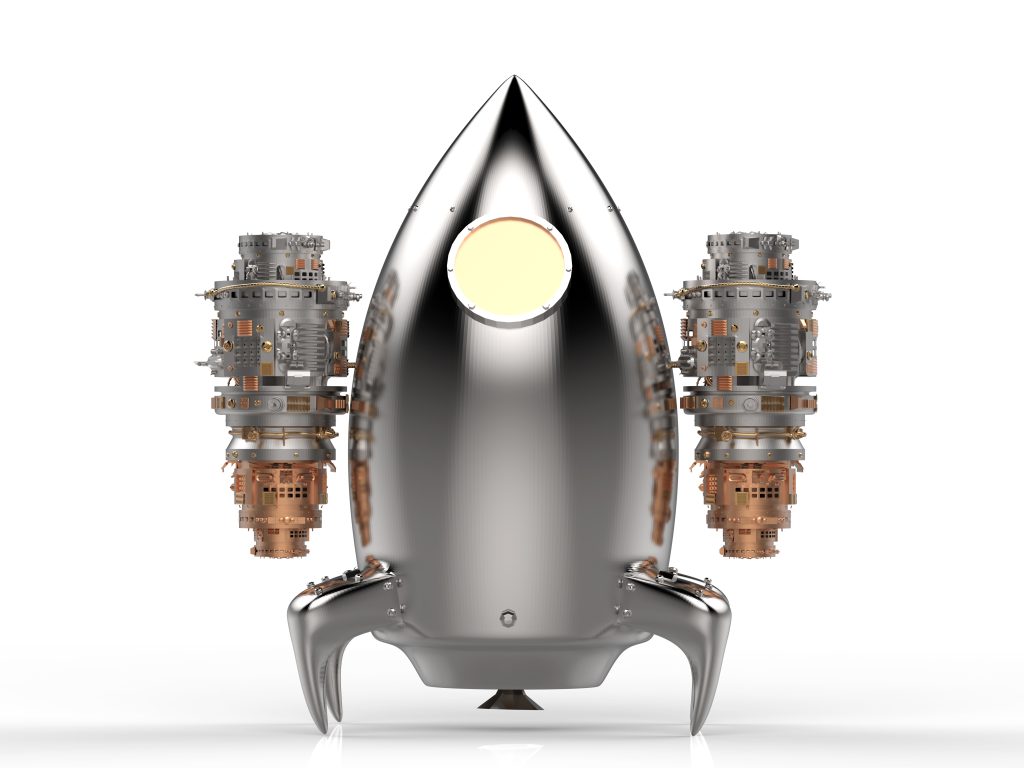

Rocket Engine Components Overview

To understand the functionality of model rocket engines, it is essential to grasp the key components that contribute to their propulsion and performance.

- Fuel composition: Model rocket engines primarily use solid propellants like black powder, composite propellants, and high-powered rocketry fuels. Experimenting with different fuel types can optimize engine performance based on factors like availability, burn rate, safety, and legal restrictions.

- Thrust dynamics: Thrust is the raw power output of the engine, propelling the rocket upwards. Impulse, affecting the duration of the power boost, works alongside thrust to sustain altitude. Both factors play a crucial role in determining the rocket’s peak altitude and trajectory.

- Ignition process: The ignition process is initiated by the igniter, sparking the combustion of the rocket fuel in the combustion chamber. This combustion generates hot gases that are directed through the nozzle to produce upward thrust.

- Engine reusability: While some model rocket engines are single-use, others, like reloadable engines, offer reusability by allowing fuel grain replacement. Engine reusability can be a factor in cost-effectiveness and environmental sustainability.

- Altitude optimization: Achieving optimal altitude involves fine-tuning the engine’s thrust dynamics, fuel composition, and ignition process to maximize performance. Altitude optimization is crucial for reaching desired heights and achieving successful model rocket launches.

Types of Rocket Engines

Differentiating model rocket engines based on their design and functionality provides valuable insights into the diverse options available for enthusiasts. When considering engine selection, it’s essential to conduct a performance comparison to determine the most suitable option for your specific needs. Single-use engines are convenient for beginners, while reloadable engines offer the advantage of reusability through fuel grain replacement. Hybrid engines, blending features of liquid and solid-propellant engines, cater to advanced users seeking a unique experience. Fuel optimization plays a crucial role in maximizing engine performance, so experimenting with different fuel types like black powder, composite propellant, and high-powered rocketry fuels is recommended. Safety guidelines should always be followed when handling and launching rocket engines, ensuring proper thrust analysis to achieve optimal results in both altitude and speed. By understanding these distinctions, you can enhance your model rocketry experience and achieve successful launches.

Thrust, Impulse, and Performance Factors

Analyzing thrust, impulse, and performance factors is crucial for optimizing model rocket engine functionality and achieving desired launch outcomes.

- Ignition Techniques and Safety: Proper ignition techniques are essential for a safe and efficient launch. Ensuring safety measures are in place before ignition is paramount to prevent accidents.

- Burn Rate Optimization: Adjusting the burn rate of the rocket fuel can significantly impact thrust and impulse, affecting the overall performance of the model rocket.

- Impulse Duration and Altitude: The duration of the impulse generated by the rocket engine directly influences the altitude the rocket can reach during flight.

- Thrust Variation and Trajectory: Variations in thrust output can cause deviations in the rocket’s trajectory. Understanding and controlling thrust variations are crucial for a stable flight path.

Consider conducting performance analysis and experimentation to fine-tune these factors and enhance the overall effectiveness of your model rocket launches. Experimenting with different variables can lead to improved performance and a more satisfying rocketry experience.